3d cad construction without compromise

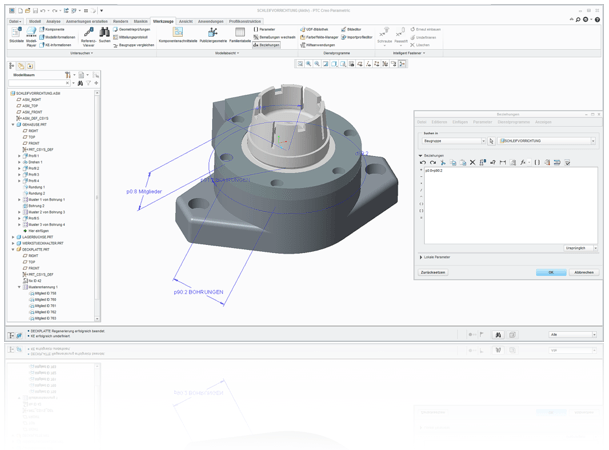

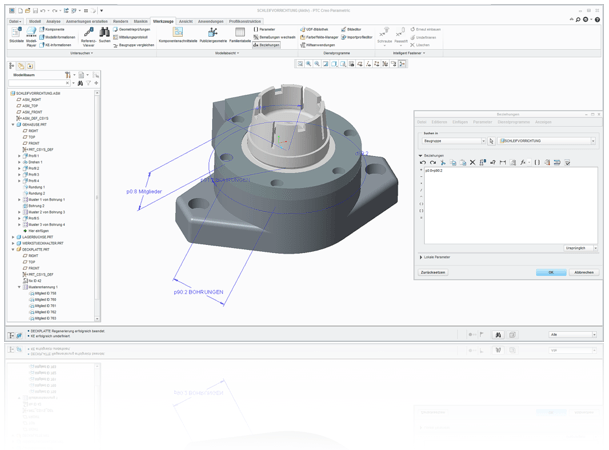

Based on the proven technology of Pro/ENGINEER® and chosen by tens of thousands of companies world- wide, PTC Creo Parametric offers the newest, most innovative 3D CAD capabilities for your detailed design process. As a design professional, you can’t risk having CAD tools that compromise your product, process, or productivity. With the software, you never compromise because you have the exact tools you need to get the entire job done accurately and quickly.

3D solid modeling

- Create precise geometry, regardless of model complexity

- Automatically dimension sketches for fast, easy reuse

- Quickly build robust engineering features such as rounds, chamfers, holes, and more

- Create part variants using family tables

Robust assembly modeling

- Enjoy smarter, faster assembly modeling performance

- Create simplified representations ‘on-the-fly’

- Share lightweight yet fully accurate model representations using the unique ShrinkwrapTM tool

- Leverage real-time collision detection

Key benefits

PTC Creo Parametric offers for parts and assemblies near unlimited possibilities for 3D solid modeling including powerful functions for creating 2D and 3D draftings and bills of material (BOM‘s).

In addition Creo Parametric comes with support for many more functional areas:

- Increase productivity with more efficient and flexible 3D detailed design capabilities

- Quickly and easily create 3D models of any part or assembly

- Dedicatedtoolsetforworkingwithlarge assemblies

- Createmanufacturingdrawingsautomatically with complete confidence that they will always reflect your current design

- Improve design aesthetics with comprehensive surfacing capabilities

- Repurpose neutral and non PTC CAD data from customers and suppliers easily, avoiding the need to convert files or recreate 3D models from scratch

- Instant access to a parts library including screws, bolts, nuts, and washers

- Getinstantaccesstocomprehensivelearning materials and tutorials from within the product to get productive faster

Further functions of PTC Creo

Technical surfacing

- Develop complex surface geometry using sweeps, blends, extends, offsets, and a variety of other specialized features

- Trim/extend surfaces using tools such as extrude, revolve, blend, and sweep

- Perform surface operations such as copy, merge, extend, and transform

- Define complex surface geometry

Freestyle surfacing

- Quickly create freeform shapes and surfaces using sub-divisional modeling capabilities

- High-quality, parameterized surfaces can be immediately reused in a 3D detailed design process

- Multilevel subdivisional modeling for more control over the surface, enabling finer detailing without altering the existing shape

- Parametrically control Freestyle geometry by aligning to existing curves or edges with tangency control

Weld modeling and structural framework design

- Optimized user interface for the structural framework design process

- Define joining requirements

- Extract valuable information from the model, such as mass properties, clearances, interferences, and cost data

- Easily produce complete 2D weld documentation

- Intelligent component library and automatic creation of downstream deliverables for faster frame design than standard techniques

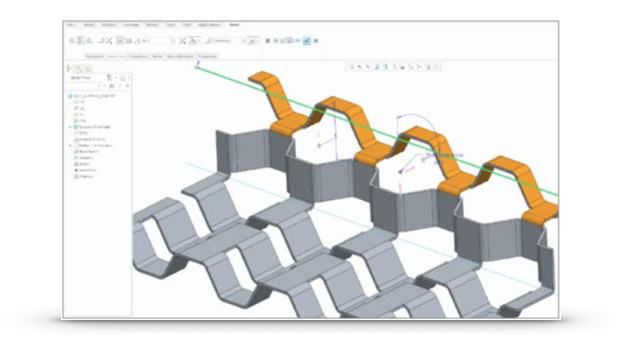

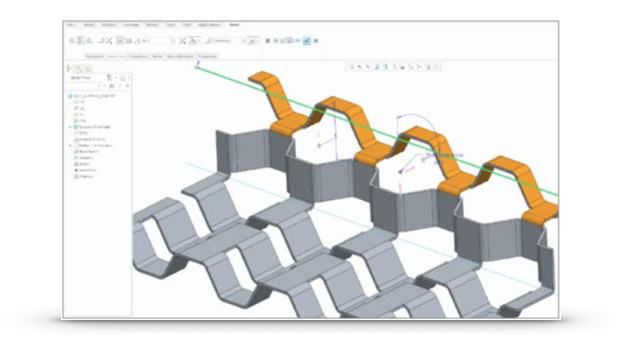

Sheetmetal modeling

- Create walls, bends, punches, notches, forms, and reliefs using the streamlined user interface

- Automatically generate flat patterns from 3D geometry

- Use a variety of bend allowance calculations to create flat patterns of the designs

Digital human modeling

- Insert and manipulate a digital human inside your CAD model

- Gain valuable insight about interactions between your product and people who manufacture, use, and service the product earlier in the design cycle

Analysis features

- Perform basic static structural analysis on parts and assemblies

- Validate the kinematic motion of your design

- Interoperability with PTC Mathcad® engineering calculation software lets you integrate PTC Mathcad worksheets with your design to predict behavior and drive critical parameters and dimensions (PTC Mathcad optionally available)

- Add Microsoft® Excel® files to your design

- Integrated analysis and measure tools including draft and 3D thickness evaluation

Graphic experience and integrated design animation

- Shade with reflections for displaying different material classes such as metal, glass, paint, and plastic. Produce realistic interaction representations of these appearance types on the model while still being able to dynamically make changes

- Create accurate, photorealistic images of products quickly, while rendering even the largest assemblies

- Make dynamic geometry changes while maintaining effects such as shadows, reflections, textures, and transparency

- Create assembly/disassembly animations directly from the modeling environment

- Reuse models easily, with the option to include mechanism simulation

Design for Additive Manufacturing

- Define settings for multiple 3D printers

- Position, scale and show a clipped view of the 3D model and support material on the printer tray

- Quickly perform 3D printability checks and easily correct identified issues

- Print parts and assemblies, define surface finishes, materials, colors and calculate build and support material directly from PTC Creo using a Stratasys Connex printer

Data exchange

- Work with a number of standard file formats including STEP, IGES, DXF, STL, VRML, AutoCAD DWG, DXF (import of 3D with associated 2D), ACIS import/export, Parasolid import/export

- With the use of Unitetechnology, convert data from other CAD systems including: CATIA, Siemens NX, SolidWorks, Autodesk, and SolidEdge

- Incorporate non-PTC Creo data directly into their designs without creating additional business objects or files to manage

- Support export of non-PTC Creo formats (CATIA, Siemens NX, SolidWorks) as well as associative updates with additional purchased capabilities