With the new update to version 5.0, SolidSteel parametric for SOLIDWORKS has expanded its functionality and improved existing features.

At the heart of the new release are the new "Custom Joints" and "Bracing" features. Both functions significantly increase the level of automation and offer enormous time savings in daily work.

The release is available right now, get the details about the changes and new features in the new version below:

Functions

Miscellaneous

Detailed documentation / training manual SolidSteel parametric v5:

Custom Joints

Custom JointsSounds harmless enough, but if ever there was a new feature in SolidSteel Parametric that was a game changer, this is it!

Anyone familiar with SolidSteel knows that all kinds of connections, such as frame corners, end plate connections, etc., could be created on the fly with all the details such as bolted connections or stiffening ribs.

However, the problem was that these quick steps had to be repeated as often as the connection appeared in the design - the time required added up.

The new Custom Joints feature allows you to teach frequently used joints once, save them in the database, and insert them into your design with just a few clicks. A detailed preview of the joint is displayed immediately upon insertion, so you can keep track of the number of individual joints that have grown over time.

It doesn't matter if the joint consists of component combinations such as end plates, haunches, cuts or notches, for which SolidSteel has its own tools, or if your individual joint is a complex construction of individual plates, round or rectangular tubes. Anything is possible, and even parametric changes (except angle changes) in the sketch are applied to the connections.

It is beyond the scope of this article to describe this feature in detail. We have created a Feature Detail for the Custom Joints feature that goes into great detail:

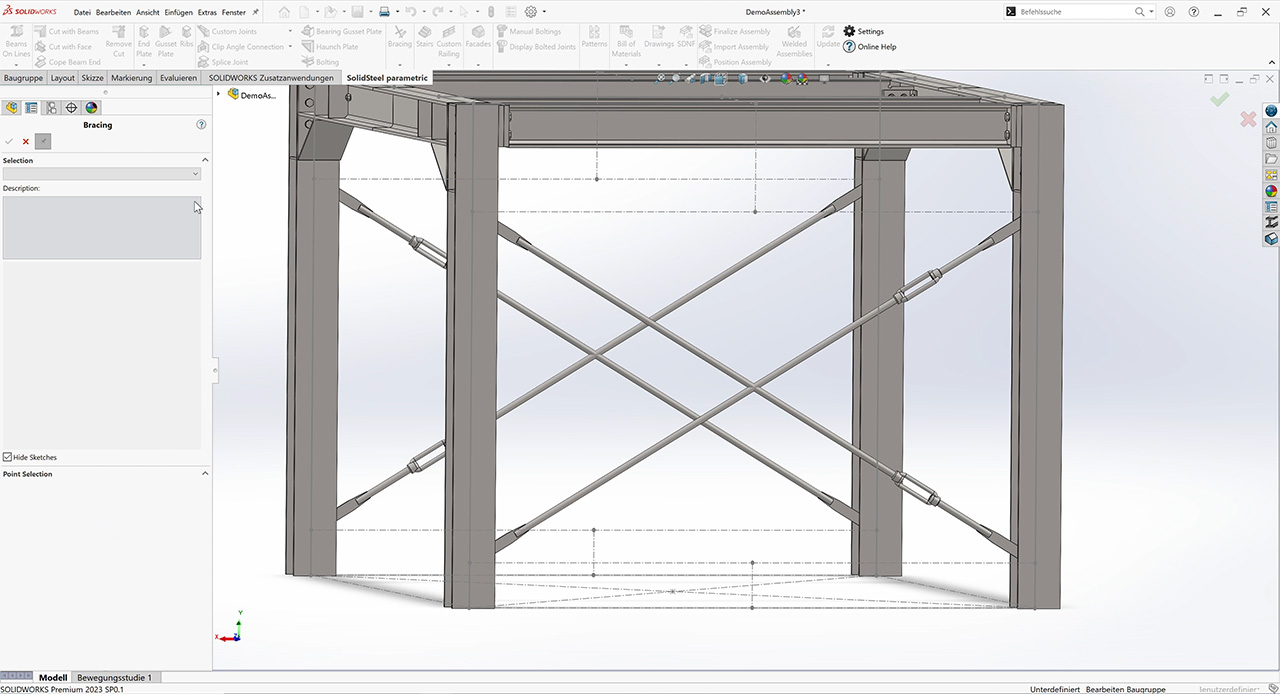

Bracings

BracingsThe new "Bracing" function also significantly increases the comfort and speed of working with SolidSteel Parametric compared to the previous version.

Previously, bracings were inserted using the SolidSteel Assembly Manager, which was not bad in general, but not very intuitive to use.

With the new bracing feature, you can achieve your goal quickly and easily. The bracings to be placed are simply designed once in a separate assembly, stored in the database and can then be used as often as required, even in different installation situations. The Bracing function's dialog guides you through the steps required for placement, showing you, for example, the order in which the reference points must be selected.

The bracing added in this way then adapts fully parametrically to the new installation situation, changing its size or shape if necessary.

Connections can also be included directly in the bracing template. If this is not the case, the connections are simply made after placement using the normal SolidSteel functions, e.g. with a gusset plate.

The use of the bracing feature is shown in the second video embedded above (New Features in SolidSteel parametric) starting at minute 5:45.

We have also prepared a separate feature detail for you on how to use the new bracing feature, showing all the steps from creating the templates to inserting them into the structure:

Haunches

HaunchesThe functionality of the haunch tool has been extended.

Placement of haunches is now also possible on round surfaces, such as round tubes.

A rotation setting option has been added to the dialog to simplify exact positioning.

Cuts

CutsMiter cut with matching angle for different profile sizes.

In most cases, miter cuts are exactly 45°. However, in situations where two profiles of different sizes are to be mitered, this standard angle results in the cut sections of the profiles being of different lengths, making it impossible to join the components.

The new advanced miter cut feature solves this problem by automatically adjusting the cut angle so that the cut lengths are exactly the same, allowing the components to be joined elegantly.

Gusset Plates

Gusset PlatesTransferring existing holes to connecting surfaces.

Previously, the hole pattern was always specified by the gusset plate, but now it is possible to transfer a hole pattern from other components to the gusset plates. This is particularly useful in cases where standardized parts are connected to the gusset plates (e.g. for wind bracings to be connected) and ensures a faster workflow.

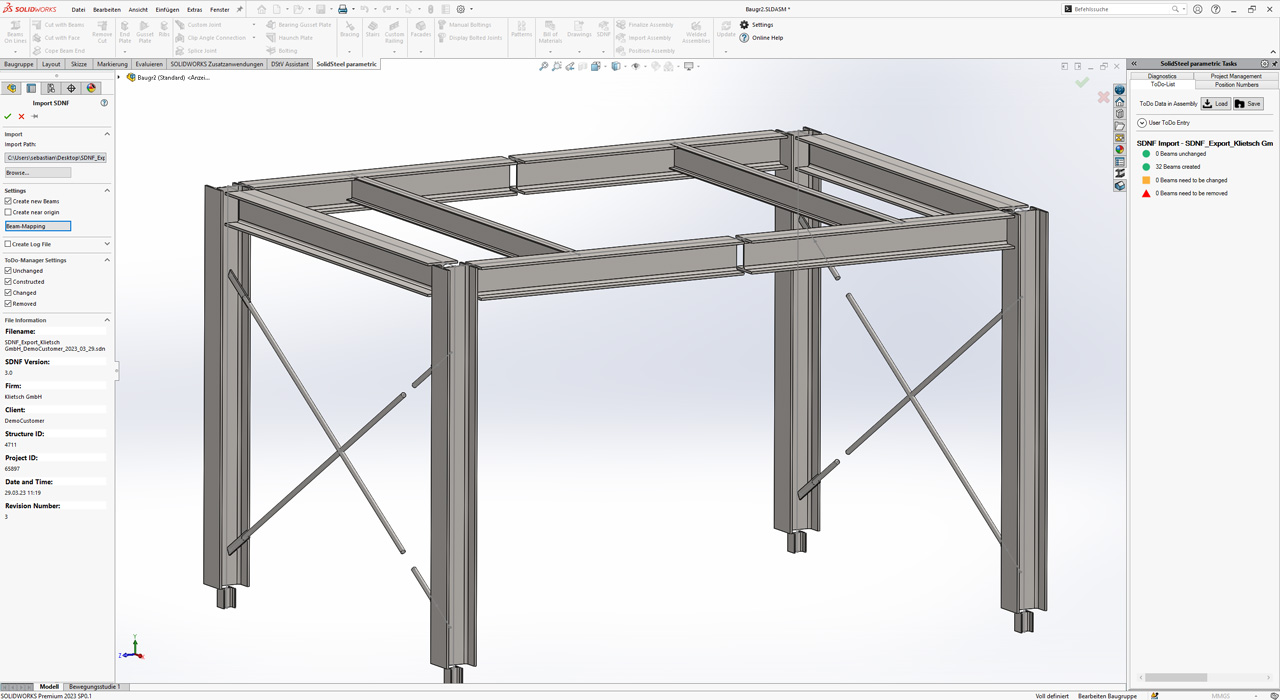

SDNF Import

SDNF ImportMapping for profiles

External structural analysis programs often use differently formatted component designations, such as "HE240B" instead of "HEB 240" in this example.

With the new SDNF mapping option it is now possible to centrally and quickly adapt these designations of imported SDNF files for all components.

Furthermore, a region detection has been added.

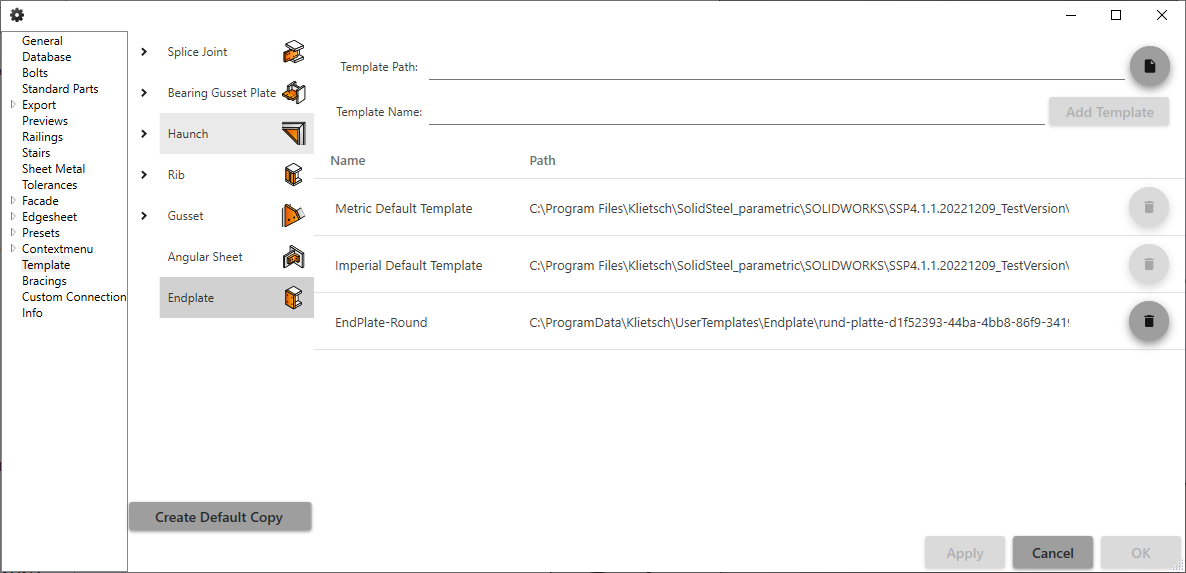

Custom Templates

Custom TemplatesUntil now, for example, the end plate function was based on standard templates oriented on various standards. These templates were generally editable by the user, but a change to the template, such as rounding the corners, would have resulted in that end plate only being available with rounded corners after the change, and no longer in the original version.

The new Template Assistant, accessible from the Settings menu, now allows you to create individual templates for all joints, such as the round end plate shown in the example on the right.

Finalize Assemblies

Finalize AssembliesFor various technical reasons, bores in SolidSteel parametric parts are normal, linearly extruded cuts in SOLIDWORKS. To facilitate the transfer of the 3D model to SOLIDWORKS Simulation/FEM, the Finalize Assembly feature has been enhanced.

All cut features can now be automatically converted to SOLIDWORKS Hole Wizard features. Since Hole Wizard features are automatically recognized by SOLIDWORKS Simulation / FEM, there is no need to manually place bolts.

ToDo-Manager

ToDo-ManagerWorking with the ToDo Manager is now even easier because selected entries are "linked" to components in CAD. When you select an item in the ToDo Manager, all related components are highlighted in 3D. The components involved can also be adjusted later.

In the new version of SolidSteel parametric, in addition to the well-known reference log file, the results of a reference check from the Diagnostics tab are also entered in the ToDo Manager for better user comfort. Of course, only the faulty references are entered into the ToDoManager.

With the new reference function, all references of a component can be displayed in an overview and edited if necessary. This function can be accessed via the context menu by right-clicking on a component in 3D or via the diagnostic tool in the Task Pane.

Miscellaneous and bugfixes

Miscellaneous and bugfixes

Settings dialog revised:

Tree structure for various subitems

Path transfer for parts lists and drawings

Load routine for dll files adapted to solve problems with NewtonSoft.Json.dll

Send error report to support forwards to mail program again

Message about missing SSp license extended:

Informs if no license available or license server not reachable

Railings:

Fixed bug with side-placed railings that the manual input of the side offset was incorrectly taken into account

Ribs:

Fixed error with presets

Fixed error when changing preset and number

Cuts:

bugfix for surface cut at curved profiles

Improvements in contour cutting

ToDo Manager:

Bugfix at component selection

Bugfix for clamp length transfer

Important Notes

Important NotesNew passwords are required for the installation.

You can obtain the new passwords:

from the Klietsch PasswordCenter (if you are a direct customer)

from the sales partner that you bought the product from.

Request "Update Passwords" for a version update.

Please add the update passwords to the license file. Together with the existing passwords the new version will be unlocked.

DSTV Assistant users will have to update it to v3.0 to ensure proper function with SolidSteel parametric v5.0.

You have additional questions about this topic? Our experts are pleased to help you. Just send us a Message or give us a call at +49 271 23167 0.